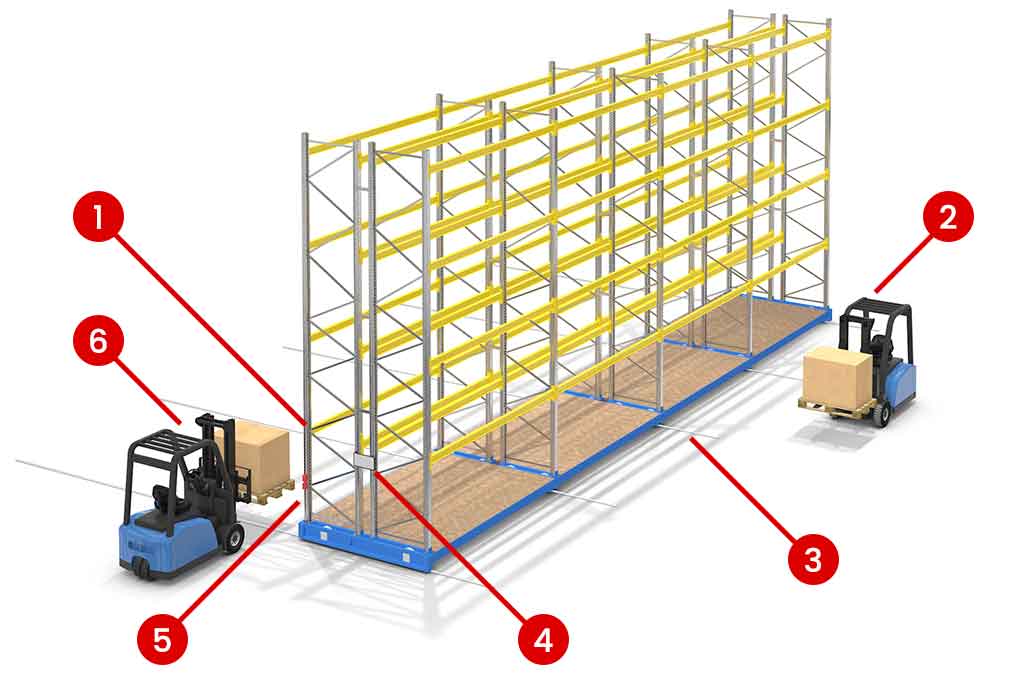

Mobile Racks

Parts, accessories, components

- Forklift count

- Additional transmitter

- Rails and spacer bracket

- LCD display, auxiliary control panel

- Front light barrier

- Universal remote control

Trolley

- Steel / sheet metal structure with high rigidity and very narrow tolerances

- Virtually unlimited length of each individual trolley

- Precision rotary parts, axes, wheels with particularly comfortable running characteristics

- Drive and shafts are designed individually according to load capacity and requirements

- Fully equipped with safety sensors and control electronics

The length of the trolley, and consequently of the row of racks, is virtually unlimited.

The racks are conventional OMEGA pallet racks.

We supply mobile racks complete with the required safety sensors.

Frequency-controlled drives provide smooth start-up and braking.

Light barrier system for ensuring user safety in accordance with the European Machinery Directive

Tracks and guide rails

- Tracks and guide rails are the basic prerequisite for a long-lasting, safe and trouble-free mobile racking.

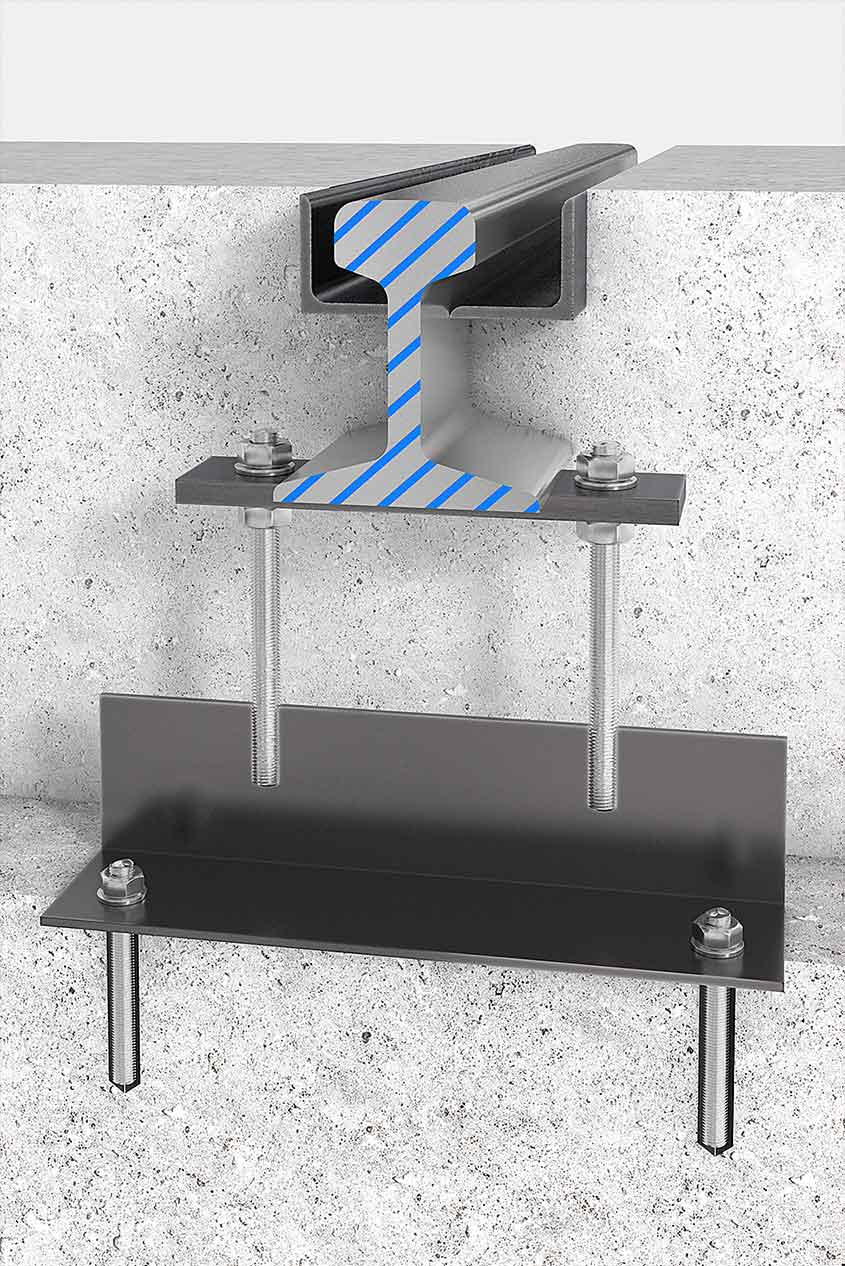

- In existing buildings where the hall floor is sufficiently statically dimensioned, flat rails with a very low installation height are used.

- For new halls and/or complete renovation of the hall floor, crane or railway profiles are levelled as tracks and guide rails on a raw concrete base or strip foundations and then grouted with non-shrink concrete mortar over the entire length.

- A measurement report is then drawn up and the areas between the rails are filled with rolled or reinforced concrete to be a flush as possible with the rail system.

Examples of various tracks and guide rails

Flat rails 80/100 x 30

Rail made of flat bars with guide groove. 40 – 60 mm are already sufficient for installation.

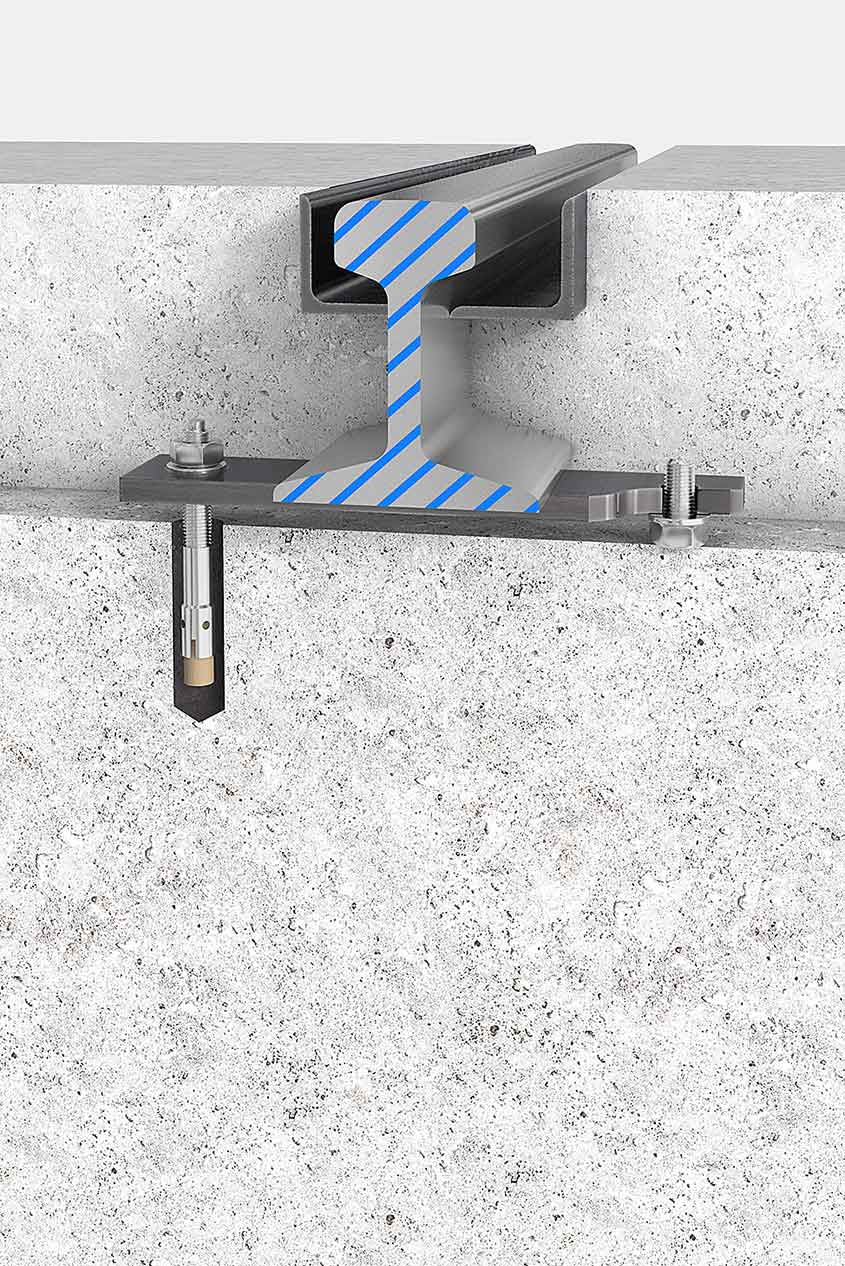

Crane rails 93/18

Rails made of this profile are used for new hall floors. The guide rails are provided with lateral angle irons to limit the concrete filling.

Crane rails 93/18 with spacer bracket

Guide rails on spacer brackets with lateral angle irons for limiting the concrete filling

Control of the trolley

- Universal remote control for controlling the mobile racking from the forklift

- Additional transmitter for several forklifts

- Switch-cabinet-independent, stationary auxiliary control panel (cold store)

- Front light barrier as safety check for persons in the aisle

- Counting of forklift entries and exits for automatic aisle release

- Control of the lighting is only where the aisle opens

- Cooling/night position: all trolleys move apart for better circulation of cooling air

- Picking position: All trolleys move apart for manual picking

The lanes are opened via a simple remote control.

The mobile racking is supplied by GALLER with the required control technology.

Signal lamps warn about a moving rack.

Each trolley is equipped with an EMERGENCY STOP.

A front light barrier stops the system, in the event that a person enters a closing lane.