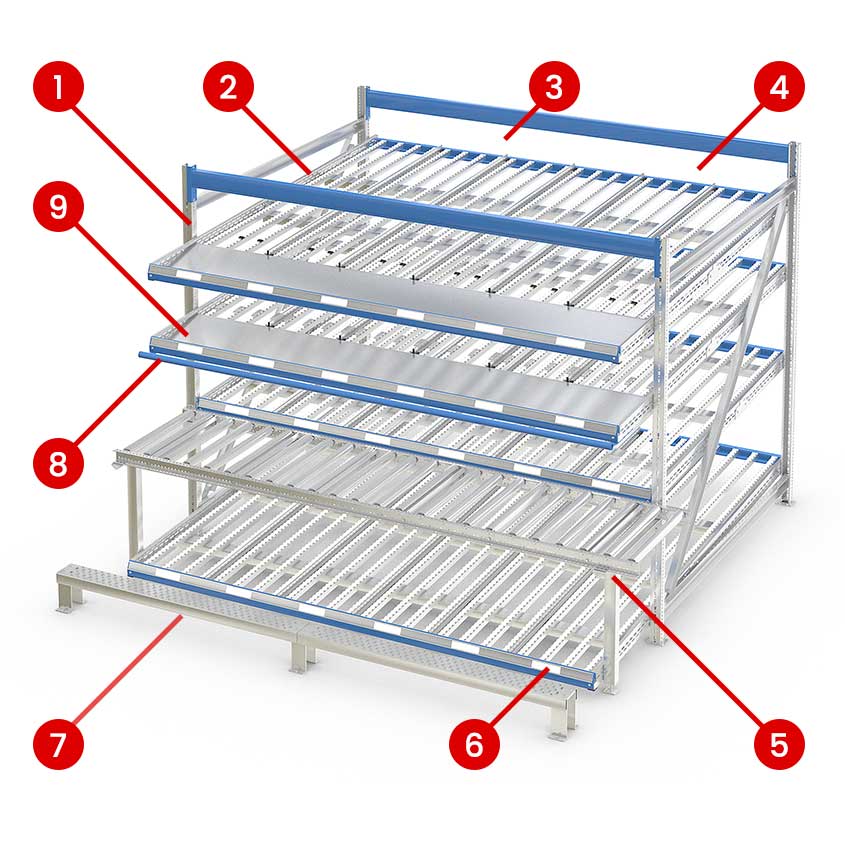

Order picking flow rack

Parts, accessories, components

With a wide range of accessories, you can configure your GALLER order picking flow levels exactly to the container shapes and sizes you use. This makes it easy to adjust the height and inclination of the flow frames, and bay widths and flow depths can be freely selected. With the system components, you can also customise the rack front or the removal area for optimum ergonomics.

- Support frame system

Support adapter - Flow frames

- Wire insertion aids

Guide rails - Standard roller rails

brake rollers,,

brake rollers,,

push-back safety device,

overrun shoes - Conveyor brackets

- Scanner rails

- Steps

- Handles

- Picking tray

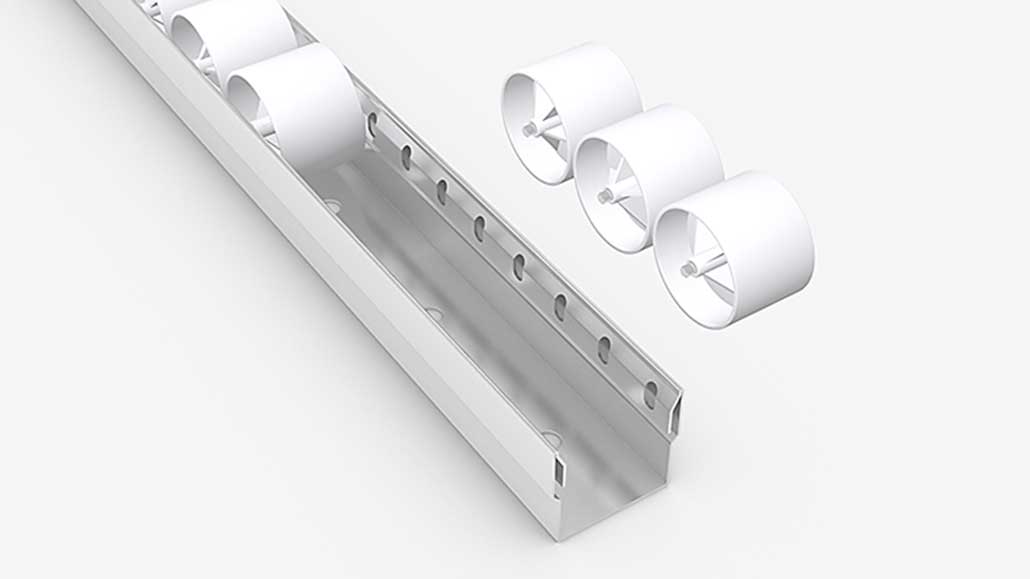

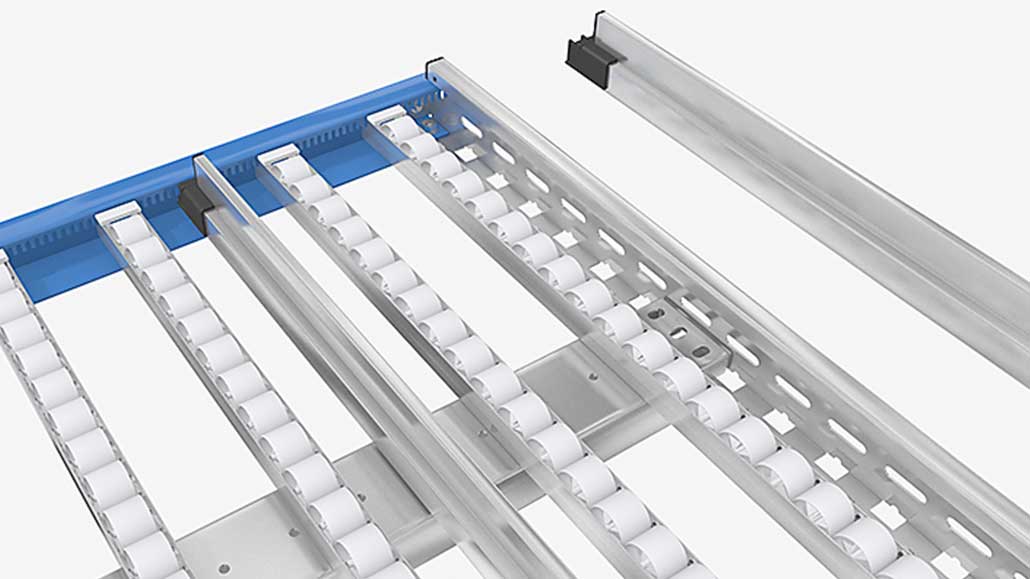

Roller rails

- The rollers are the heart of a flow rack for order picking.

- At GALLER, the rollers are mounted on steel axles – for best running properties, long service life and particularly quiet running with high load capacity (12 daN).

- The rollers are made of high-quality, natural-white plastic.

- Our standard rollers are also suitable for use at low temperatures.

- Highly conductive rollers (ESD version) are available on request.

- Coloured rollers are optionally available.

- The rollers are mounted in torsion-resistant, self-stabilising sheet steel rails.

- Each roller rail can be precisely configured to the millimetre according to the customer’s requirements.

- A roller pitch of 33 mm guarantees the best running properties of the cartons, boxes, etc.

- The 28 mm roller pitch provides the best running properties also for particularly small stored goods.

- The maximum length of the roller rail is between 6,000 mm and up to 20,000 mm.

- The rollers can also be used mixed, the installation height is generally 36 mm.

- Individual rollers can be replaced easily and without tools at any time.

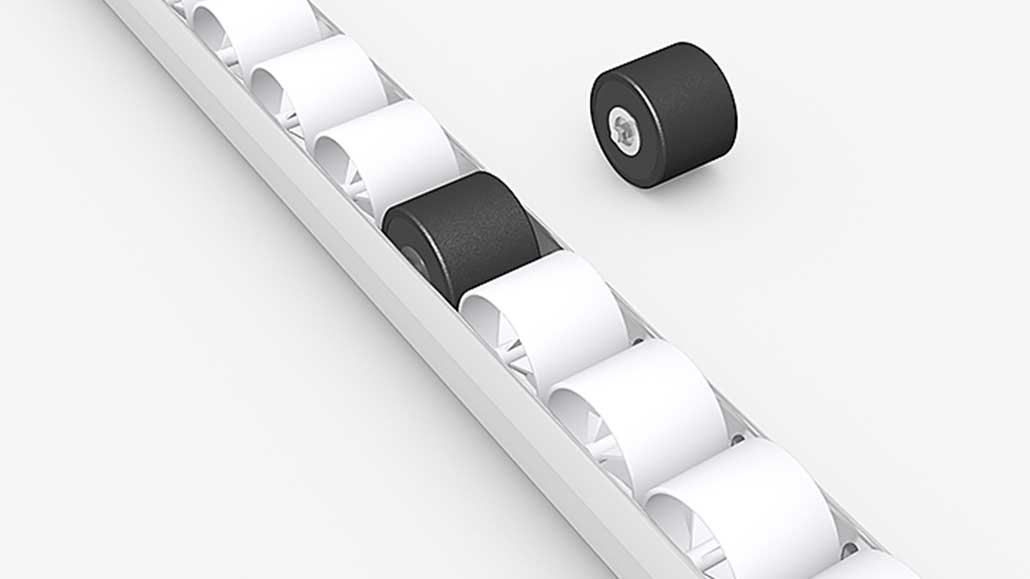

Brake rollers

- Brake rollers enable diverse applications, e.g. sorter buffers, supermarket applications or deep flow racks, particularly with a large inclination.

- They can be easily mounted by replacing the standard rollers.

- The weight range provided by GALLER is unique on the market.

Backstop

- In the case of automatic loading, the backstop prevents the stored goods from running back.

- It consists of plastic stoppers mounted on steel axles.

- A special version with an aluminium/steel combination is also available for the harshest use and special heights.

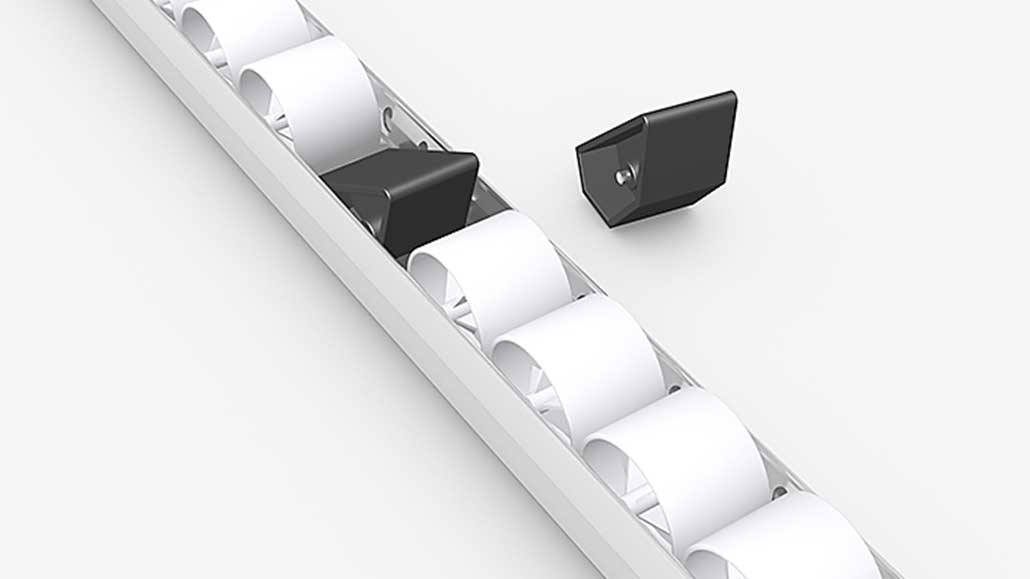

Overrun shoes

- Overrun shoes made of plastic reduce the impact speed.

- Overrun shoes replace the continuous stop.

- They enable intervention between the channels.

- The overrun shoes are inserted into the roller rails with steel axles.

- Typical use is in flow channels of automated miniload systems (AMS) or for mounting on cross members in the pallet rack.

Brake clamp

- Brake clamps (spring steel or galvanised) brake the stored goods before the stop.

- It is simply placed over three rollers.

- Attention: no independent restart possible!

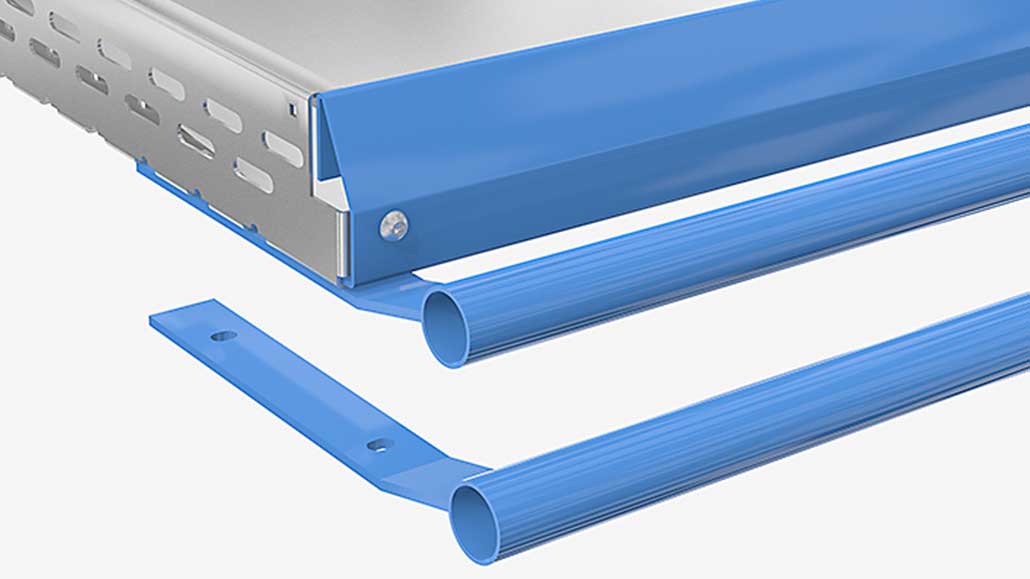

Guide and separation rails

- Guide rails are used to separate two flow channels.

- Guide rails are like crash barriers for the stored goods in the channel.

- The guide rails cover the entire depth (up to 20 metres) of the flow channel.

- The respective channel width can be easily adjusted without tools in the 7.5 grid.

- The guide rail is also available in a stable tube version (20 mm diameter).

- We develop individual guide rails for special applications.

Wire insertion aids

- For channel separation for flow depths up to 400 mm

- They are supplied including special beam and back panel, each with special perforations.

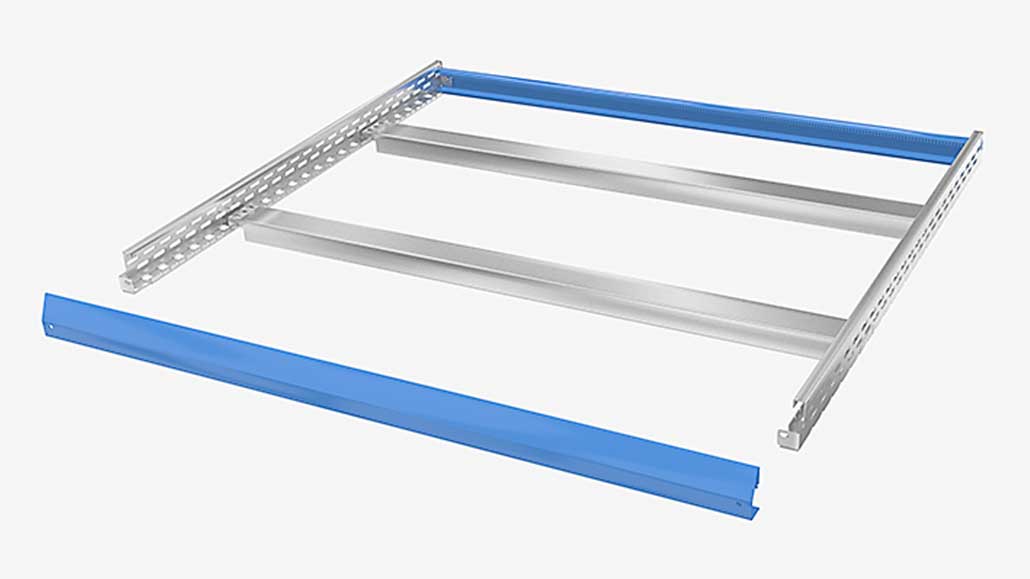

Flow level type Combi

- The frame of a flow level is designed for max. 170 kg/sqm.

- a very flexible and inexpensive variant

- high stability due to corner screw connection

- very easy to assemble thanks to tool-free insertion of the beams, roller and guide rails

- The channel division can also be changed easily and quickly at a later date.

- Spread protection prevents the mounted rails from shifting.

- Picking trays (inclination: 6° as standard) improve grip ergonomics

- RAL colours

Flow level type Heavy Load

- Design as for type Combi but up to (300 kg/sqm) loads on one level

- The individual components are screwed together.

- The frame is usually bolted to the rack supports or adapters.

- The maximum bay width is 3,000 mm.

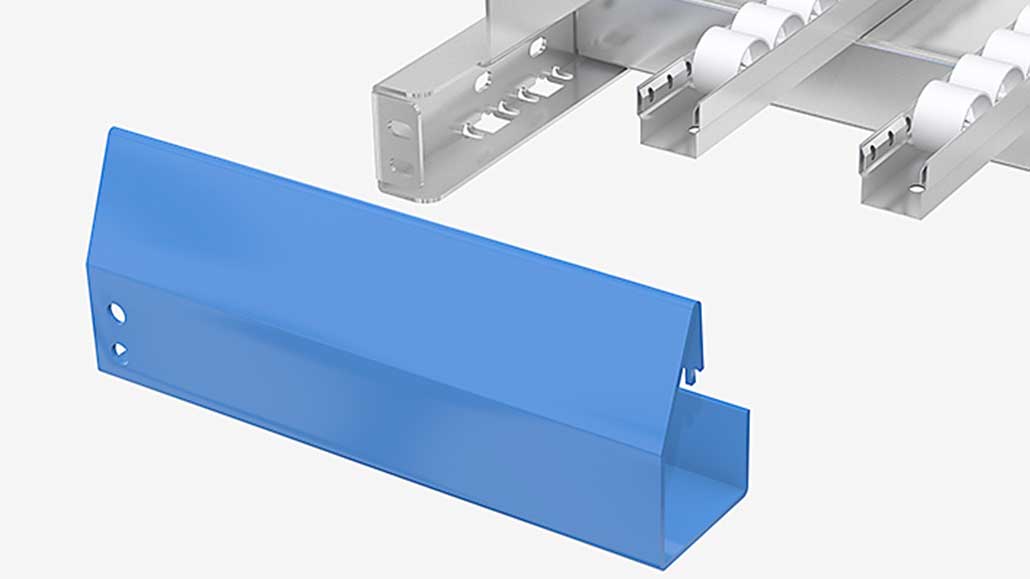

Picking tray

- The tray is used to place the order picking containers and is ergonomically favourably inclined by 6°.

Steps

- The steps provide better access to the upper flow levels.

- The heights and widths are variable.

- Anti-slip punching or anti-slip coating on request

- The steps are mounted on rack supports or on the floor.

Handles

- For securing the ascent when using steps

- The handles are attached to the upper flow frame.

- They are made of tubular steel, the surface is powder-coated.

Scanner rails

- They allow the channels to be labelled by inserting labels.

- The scanner rails are glued to the front and rear panels.

- Available in the standard heights of 30, 40 and 60 mm.

Conveyor brackets

- The brackets along the flow rack are used to support roller conveyors with/without drive.

- They consist of supports with adjustable feet and support brackets with individual perforation.

- Special designs (e.g. for overhead waste carton conveyors) are possible.

Flow rack

- Multiple flow levels above each other make up an order picking flow rack.

- Standalone with its own support system or integrated in an OMEGA pallet rack

- GALLER OMEGA pallet racks are optimally matched to the order picking flow levels.

- Thanks to the multi-adapter system, the flow levels fit into pallet racks from a wide range of manufacturers.

- Equipped with keyholes in 20 mm grid

- The support heights are available in 1,800, 2,120 or 2,520 mm as standard.

- The standalone framework is a flexible screw modular system.

- The support frames of the flow racks are connected by bracing bars.

- The maximum bay width is 3,000 mm.

- The crossbars are adjustable in 20 mm increments for precise adjustment of the slope.