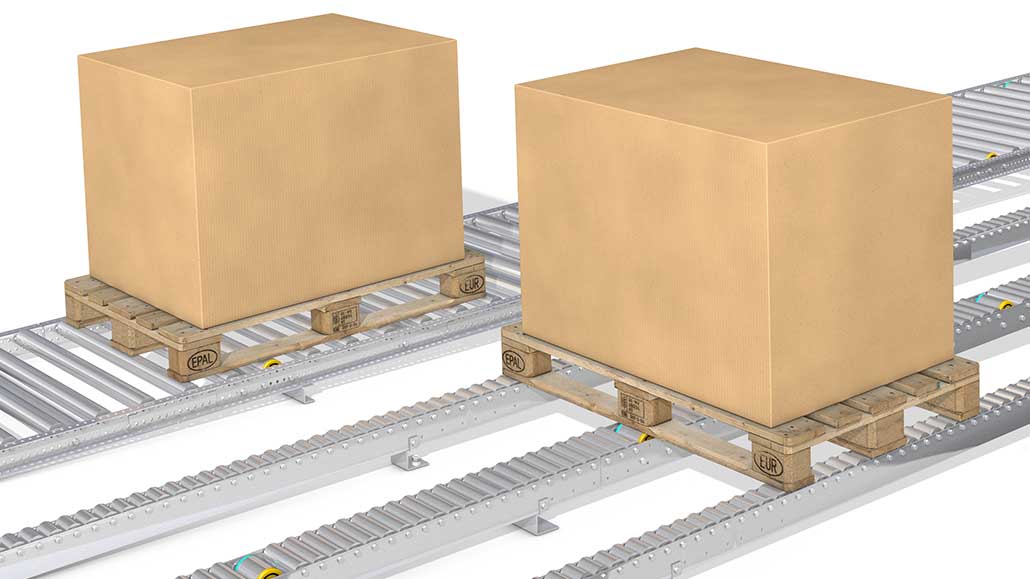

Pallet floor roller conveyor

GALLER also provides roller conveyors for mounting on the floor. The elements can be installed with or without a slope and are used, for example, in provision zones or picking areas.

Roller conveyor without slope in a provisioning zone

Floor mounted roller conveyors for order picking

The smooth-running conveyor rollers of the floor roller conveyors from GALLER guarantee you trouble-free processes and a high level of operational reliability. Pallets with weights from 200 to 1,200 kg can run mixed in the same channel. If you use special pallets: we adapt our systems to them and test the smooth functioning in our GALLER test centre.

- Centrifugal brakes provide optimum regulation of the running characteristics of all pallet types and loads.

- The spring-loaded brake mounting guarantees optimum and constant braking performance.

- Thanks to the “dynamic pre-stop”, every pallet really reaches the end stop.

- Mechanical and pneumatic separators enable the pallets to be removed without accumulation pressure.

- The particularly stable design prevents damage from forklift tines.

- All components are suitable for low temperatures: brakes, ball bearings, rollers, gearboxes.

- Removal using a hand pallet truck is possible due to the floor discharge divided into three parts.

- We provide you with guaranteed operationally reliable solutions also for pallet cages, metal pallets, plastic pallets, half pallets and special pallets.

Removal conveyor with pneumatic separator

Flow warehouse with order picking tunnel

Your advantages with floor roller conveyors from GALLER

- longitudinal and – NEW – transverse transport of pallets possible

- three-lane tracks minimise deflection and maximise operational reliability.

- excellent operating characteristics due to short roller pitch and length

- convenient removal of the pallets due to separator with foot release

- easy cleaning between the tracks

The three-lane roller conveyors support the pallet skids and minimise pallet deflection

Longitudinal or transverse transport of pallets possible

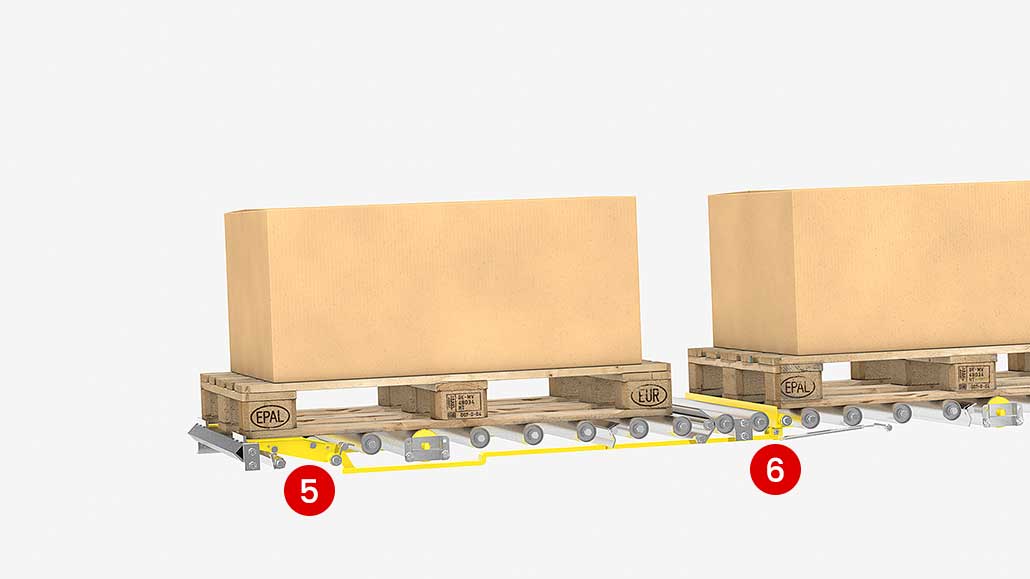

How the separator works

Empty removal element

1. Switching flag is folded upwards and indicates that the separator is open.

2. The first pallet on the roller conveyor can roll to the removal position.

Increase of the pallet spacing

3. In the area of the removal element, the first pallet accelerates and thus detaches from the following units.

4. The following pallets are braked before the bar, depending on the weight.

Separate pallet

5. The weight of the pallet presses the switching flag downwards and the separator is activated.

6. The following pallet is thus stopped at the separating bar.

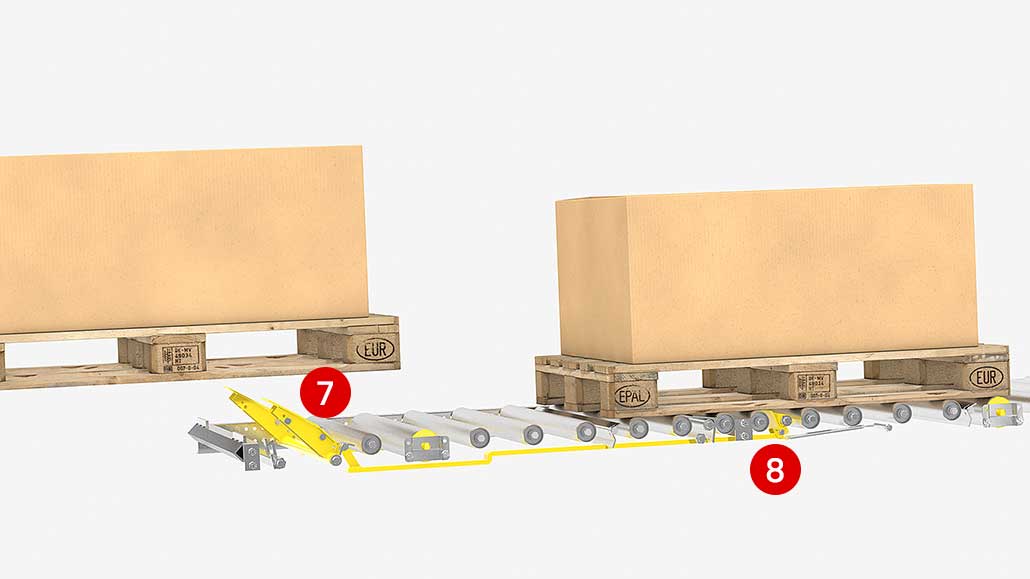

Remove pallet

7. The switching flag flips up when the pallet is removed.

8. This unlocks the separating bar again and the following pallet can roll to the removal position.