Rack systems, forklifts and space efficiency

Get more out of your warehouse!

You can realise many different designs of storage systems with the racks from GALLER. Depending on the available space, hall height or requirements for article access, you will find the optimum solution for your personal requirements with our portfolio.

Space utilisation and rack operation

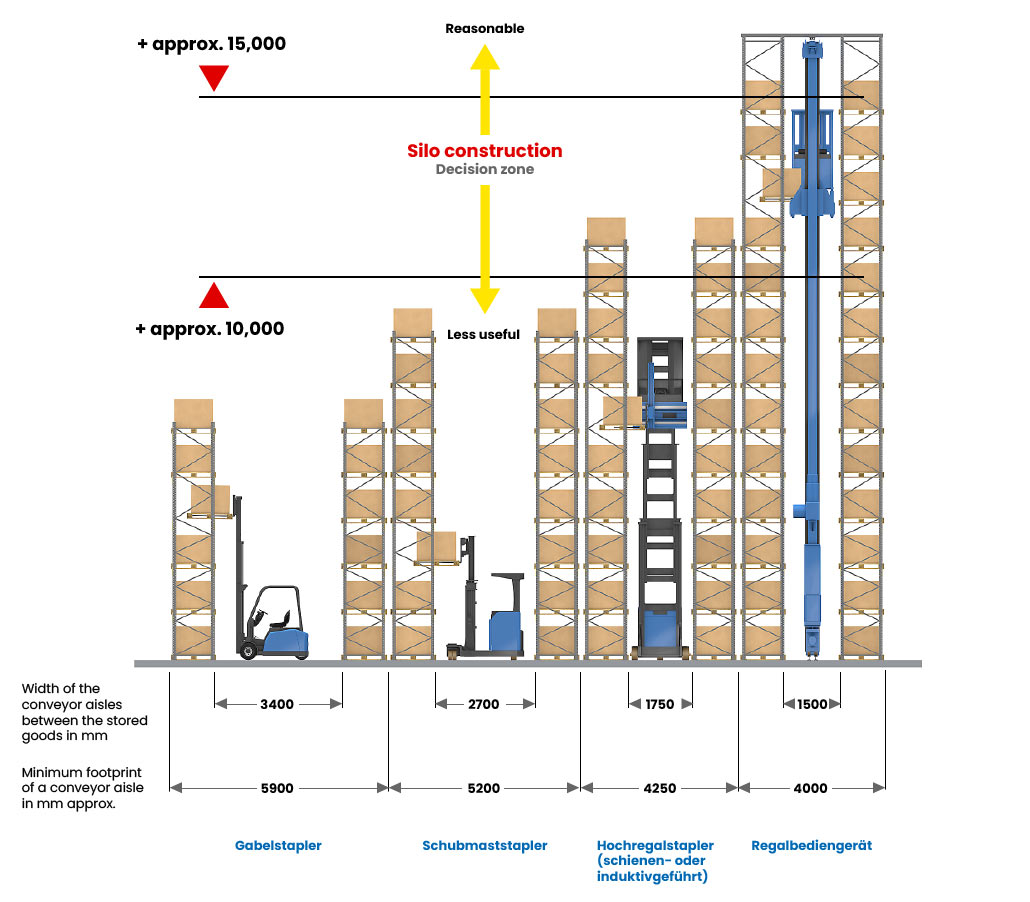

- How a rack is operated determines the storage capacity for a given space

- The aisle width of the floor conveyor system influences the degree of space utilisation of the racks

- A conventional hall is recommended for heights up to 10 m, and a rack silo above that.

- With the rack systems from GALLER you optimise your warehouse taking into account space, hall height, article access and throughput.