High bay racking Silo

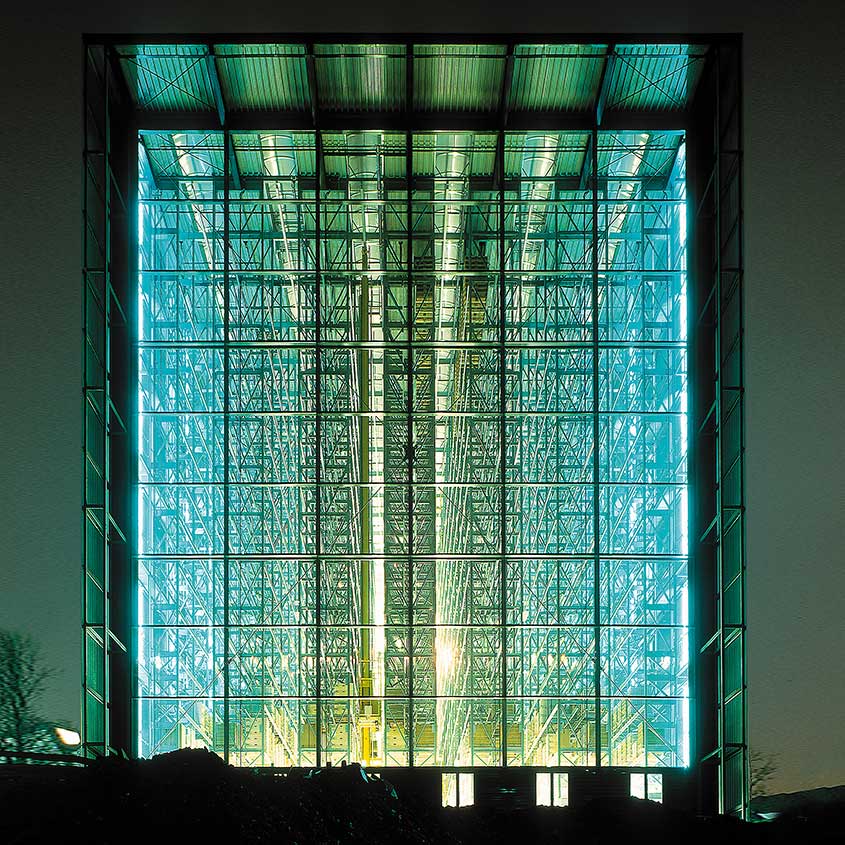

GALLER high bay racking silos allow you to store large quantities of an item with high handling rate. Thereby, the high bay pallet racking also takes on the function of a load-bearing building structure. This means that the roof and wall claddings are attached to the rack structure. With this compact design, you make particularly efficient use of the available space. With their dominant dimensions, high bay silos are striking figureheads of a company. Therefore, architectural criteria should definitely be taken into account during construction.

- The warehouse shell can be claimed as production equipment for tax purposes.

- By eliminating the construction of a separate building, commissioning is much faster and construction times are significantly shorter.

- The silo construction accommodates the load of the stored goods, the own weight of the roof/wall elements as well as wind pressure and snow load.

- From a construction height of 10 m, the silo construction becomes economically interesting.

- Modern high bay silos combine utility with innovative industrial architecture.

High bay silo of a lighting manufacturer in Lüdenscheid

The GALLER design allows for high-bay silos up to 22 m high.

Functionality

The rack aisles in the high bay silo are usually operated by automated storage and retrieval systems. Usually one automated storage and retrieval system is used per aisle. In storage warehouses with a high number of storage locations and a low access frequency, the control units can also be moved between the racking aisles via a transfer bridge and thus serve several aisles.

Toy factory, D-Rödental/Bavaria

Chocolate factory, Vila Vela/ES, Brazil

Components of the OMEGA pallet rack form the basis of the high bay silos

Established basis of OMEGA pallet racks

- The GALLER high-bay silo systems are manufactured from the proven system components of the OMEGA pallet rack.

- The load is transferred to the floor slab via four base points so that it can be dimensioned weaker and the on-site costs can be significantly reduced.

- Different shelf heights can easily be selected for each side of the double-sided rack.

- Sprinkler lines are easy to mount between the upright frames and easy to fix due to the rows of holes on the sides.