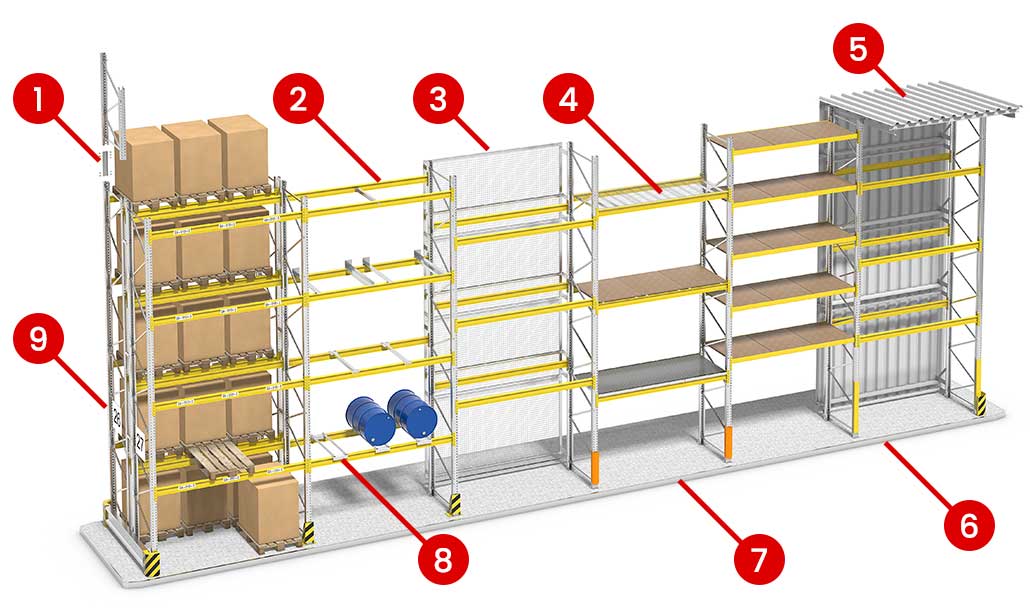

Multi-Storage Pallet Racks

Parts, accessories, components

Customise your rack

We provide an extensive range of practical accessories for our multi-storage pallet racks. Therefore, your rack system can be configured exactly for your individual application.

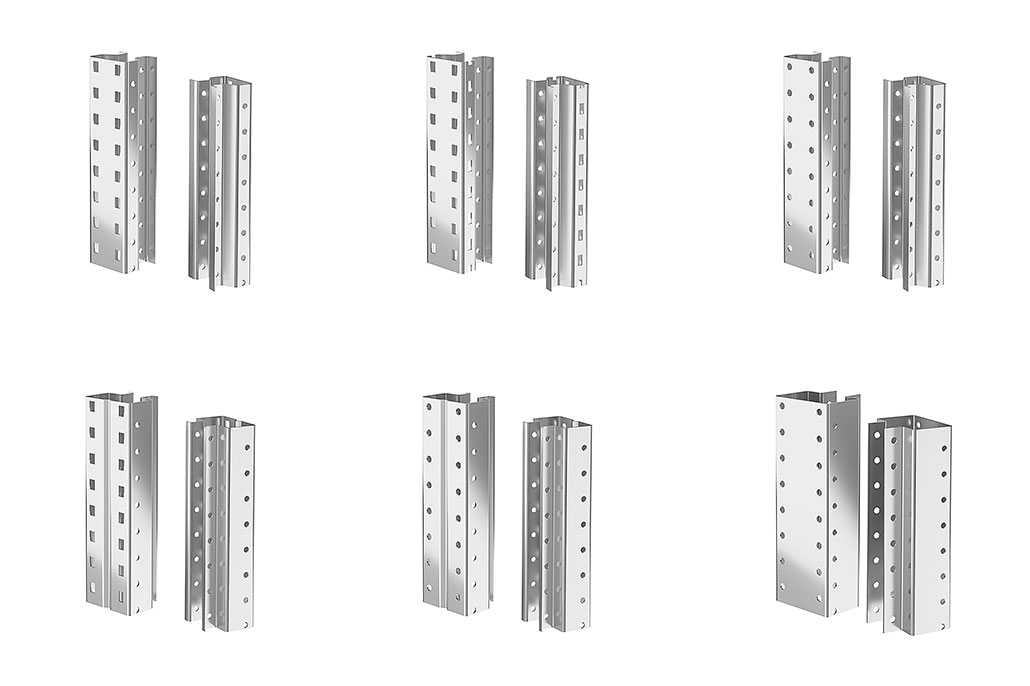

System components – OMEGA upright profiles

- OMEGA upright profiles support high loads and are particularly durable.

- Three versions of the OMEGA profiles and numerous subvariants allow for a rack upright design that can be optimally adapted to your requirements.

- Bolted design: For the OMEGA-M system, the components are bolted together on site – this reduces freight costs.

- The OMEGA-M components are strip and electrolytically galvanised.

- Welded design: For the OMEGA-S pallet rack, the frames are welded with very low tolerance specifications. Thus, the OMEGA-S system is particularly reinforced and stable.

- Thanks to its high dimensional stability, OMEGA-S is predestined for use in automated warehouses.

- When using the OMEGA-S system, there is no need for on-site frame assembly at all.

- The OMEGA-S racks are completely powder-coated in the desired RAL colours, hot-dip galvanised or cathodic dip-coated as a welded assembly.

- If you have particularly high requirements for corrosion protection, the OR6000 coating system provides the highest possible level of protection even against acids and chemicals (at least 6,000 hours salt spray test).

Examples from a large product family

The three systems OMEGA Standard, OMEGA 200 and OMEGA Special are the basis of almost every rack configuration, up to automated high bay warehouses.

OMEGA-M

Bolted frames

Standard base plate and upright connection of the bolted upright frames.

OMEGA-S

Welded frames

Standard base plate and upright connection of the welded upright frames.

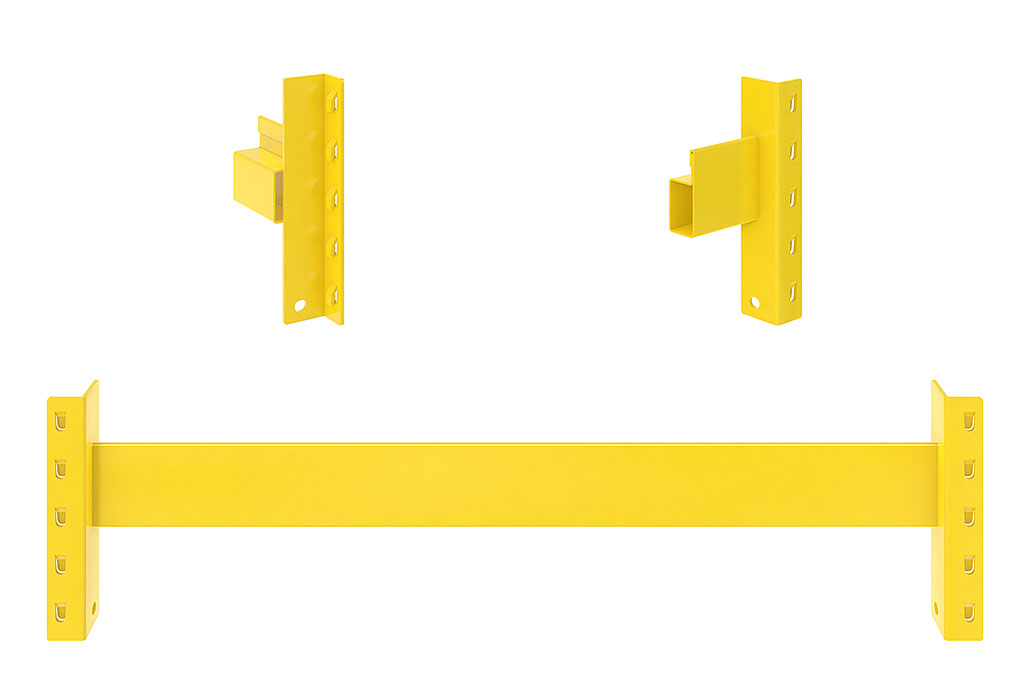

System components – Beams

Depending on the function of your rack and the required shelf load, Galler provides various beam systems. You can configure your rack very easily for your requirements with them.

- Precise, resource-saving, load-bearing: the IPG beam series, the GALLER standard in the pallet rack for all load-bearing requirements.

- IPG = “I” describes the shape, “P” stands for profile and “G” for GALLER.

- IPG beams are powder-coated as standard, hot-dip galvanised for outdoor applications. For special applications, we also provide our OR6000 coating here.

- The GF beam is used for order picking levels.

IPG beams: With three available installation heights and different sheet metal thicknesses, the beam can be flexibly designed for different shelf loads.

GF beams: The beam for order picking levels can be equipped with wooden shelves, sheet metal panels or gratings.

Accessories: Beam Elements

Deep beams “Z” centre the loading aid (pallet) and secure it against slipping off

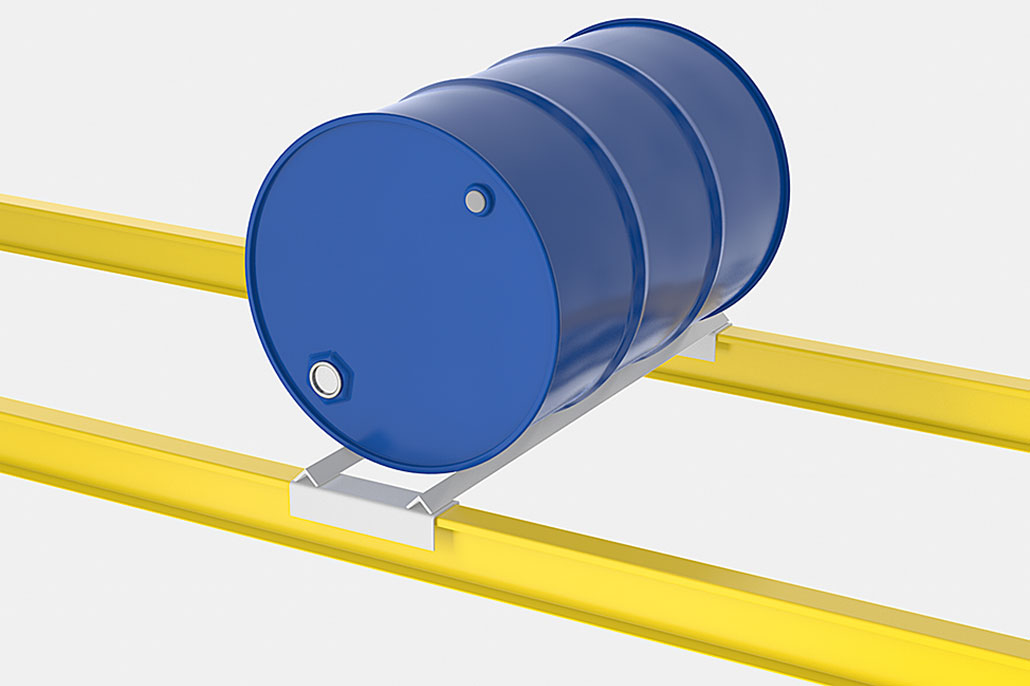

Centre welded drum supports and secure drum storage

Accessories: Rack Connections

Push-through protectors prevent pallets from being pushed too far and falling from the rack

GALLER pallet racks can also be subsequently extended in height; for this purpose, the uprights are bolted directly together or connected via butt plates, depending on the load requirements.

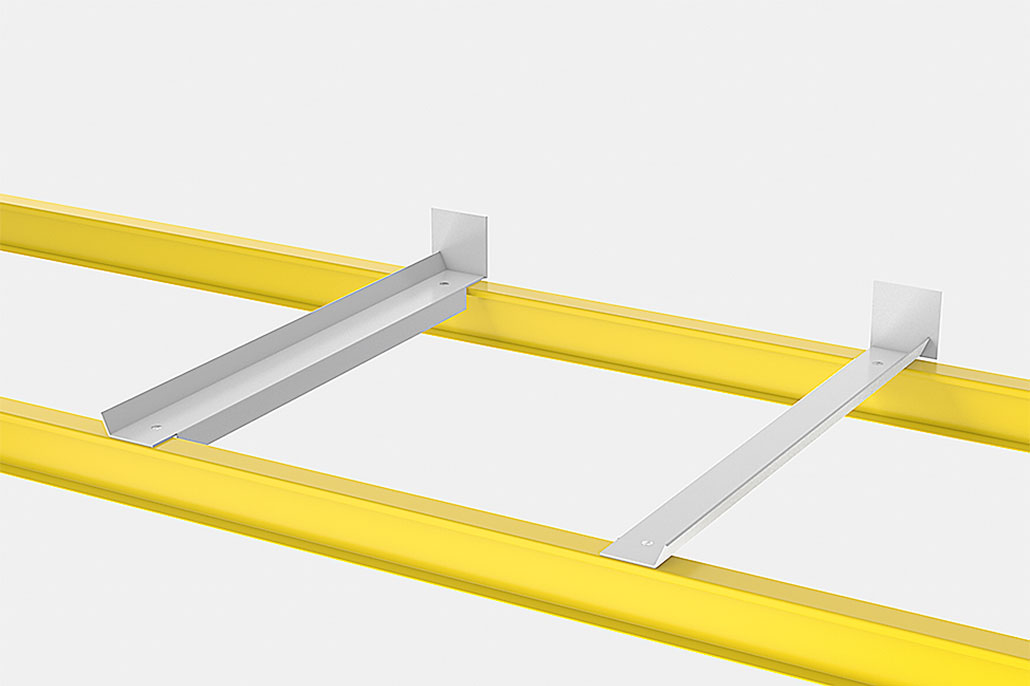

Accessories: Decking for IPG beams

With different deckings, you can also use the pallet racks for storing cartons, boxes or different, also non-standard pallet types. In addition, goods can also be stored without storage aids, e.g. bagged goods or cartons.

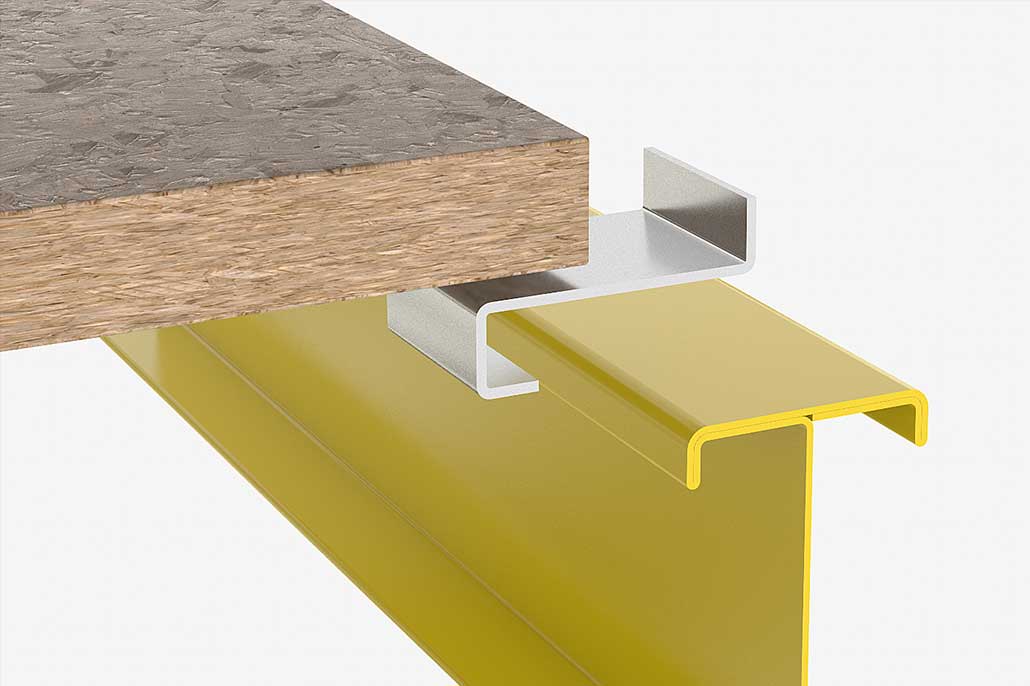

Chipboard panels

Chipboard panels are used, for example, in the order picking area and for storing cartons or boxes.

Z-plates made of sheet metal flexibly fix the chipboard panels to the IPG beams. Optionally, a Z-angle plate can be used as edge protection over the entire shelf width.

Pass-through covers and fall-through protection

Overlaid wire meshes are used to store smaller, lighter items.

Chipboard panels and wire mesh shelves are also used as pass-through protection.

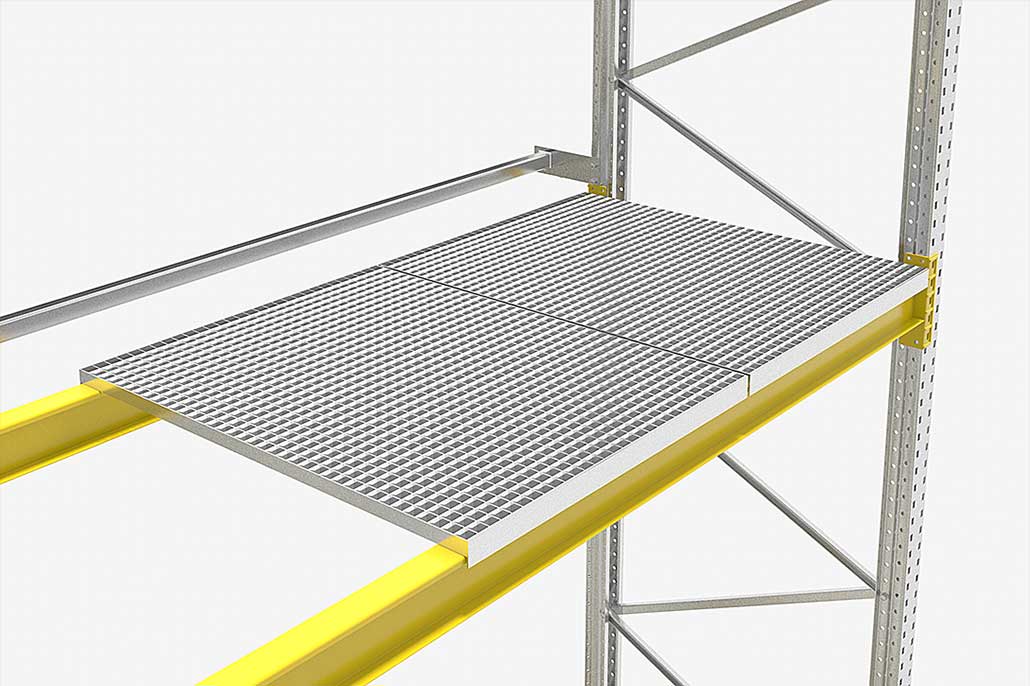

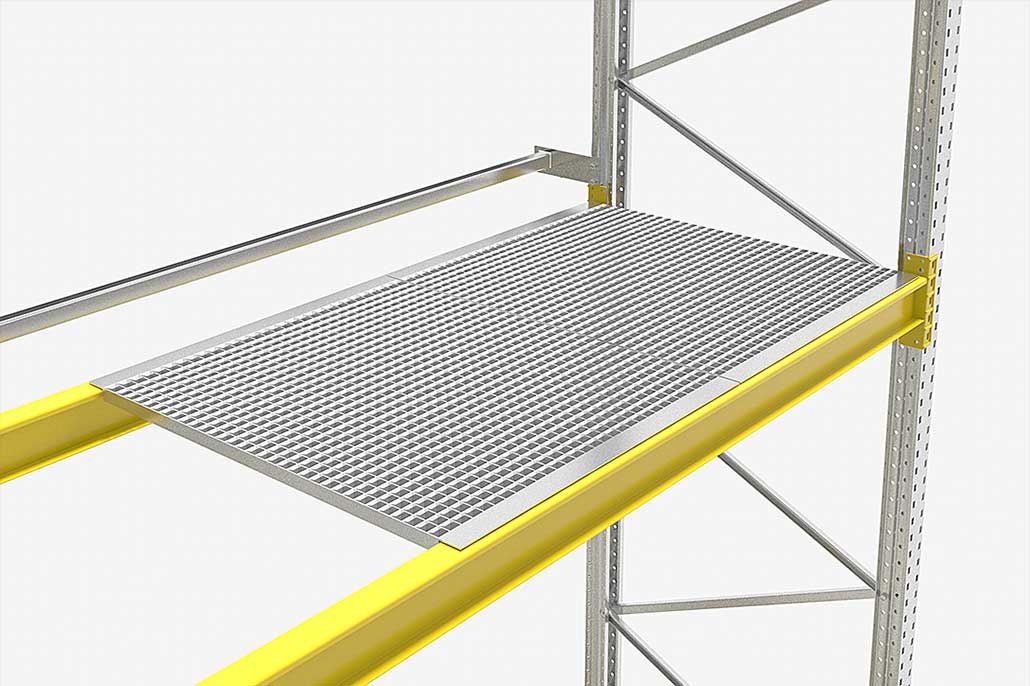

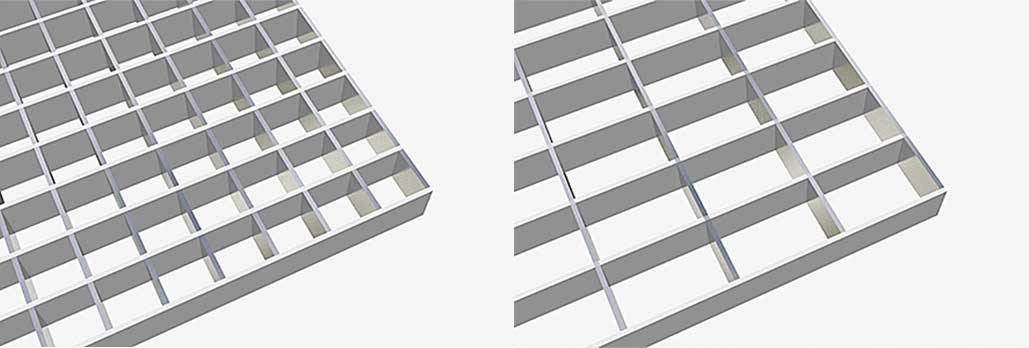

Grating

Grating shelves (laid on the left, inserted on the right) can accommodate high point loads and can also be used as shelf supports with sprinkler systems.

Different mesh sizes

Adapted to the necessary load-bearing characteristics and taking into account economic aspects, the mesh shelves are manufactured in different mesh sizes, material thicknesses and installation heights.

Accessories: Collision and crash protection

Storage facilities must be protected against damage – for example by the industrial trucks used in the warehouse – in accordance with the applicable regulations.

Galler has various impact protection elements in its range for this purpose.

Centre collision protection – standard. 8 mm thick and 400 mm high, anchored to the floor independently from the rack.

Impact protection corner at rack corners and passageways. 4 mm thick and 400 mm high, anchored to the floor independently from the rack.

Impact protection wall protects the entire front side of the racks from collision damage. Impact protection corner, 4 mm thick and 400 mm high, with strip galvanised C-profile, anchored to the floor independently from the rack.

A U-shaped collision protector (600-1,000mm high) is bolted to the upright to reinforce the upright.

Plastic collision protection

In contrast to collision protection in the corner areas of the racks, centre supports can also be directly connected to the uprights. For this purpose, GALLER provides a flexible upright protector made of high-strength plastic, which is simply “clicked” onto the uprights without tools. The colouring ensures very good visibility.

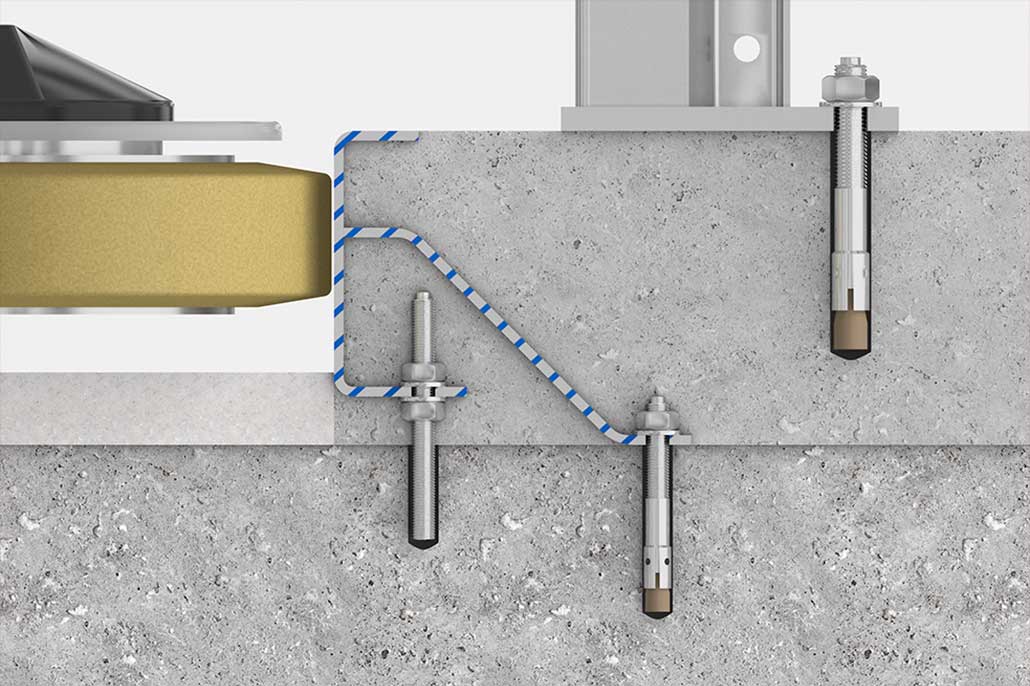

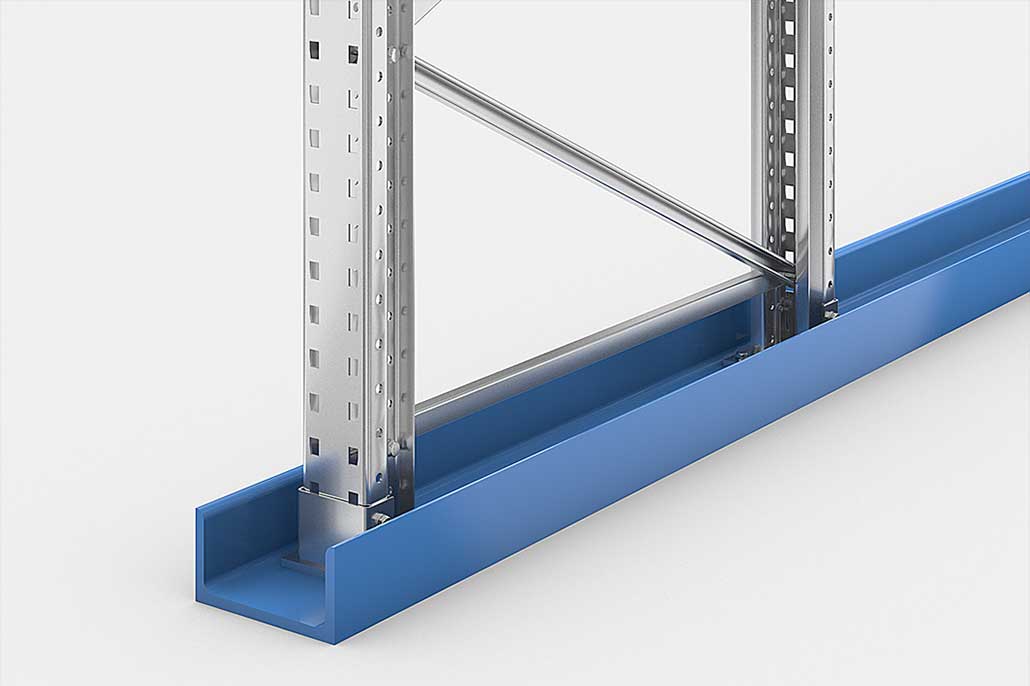

Accessories: Guide Rails

GALLER provides various guide rails for the forced guidance of industrial trucks such as high bay stackers or order picking equipment in narrow-aisle warehouses.

Guide rail U65

A low U-guide rail also allows a pallet standing on the floor to be picked up by forklift forks.

L-guide rail

An L-guide rail 100 x 65 mm according to DIN1029 made of 9 mm thick sheet steel is used for small and medium lifting heights and low lateral forces.

Entry guide

For easier insertion of the industrial truck into the rack aisle

Special U-guide rail

For levelled/non-levelled floor

Accessories: Load balancers

Load balancers distribute the point loads introduced into the floor by the rack uprights so that the underlying floor slab or concrete floor is loaded more gently.

U-load balancer or floor-side guide profile

HEA load balancer

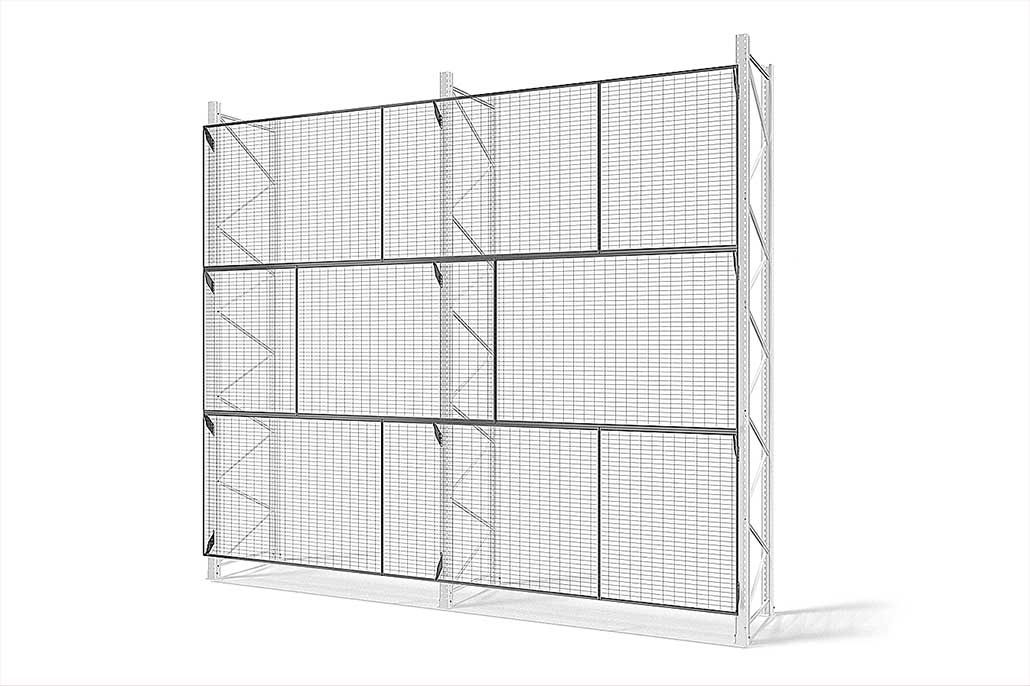

Accessories: Mesh back panels

Racks adjacent to areas accessible to persons and/or traffic routes must have reliable protection against the falling of stored goods or unit loads.

GALLER provides various mesh back panels as fall protection.

Mesh back panels according to the brick principle

Mesh back panels adapted to the respective bay widths of the rack make it easier to extend the rack system at a later date.

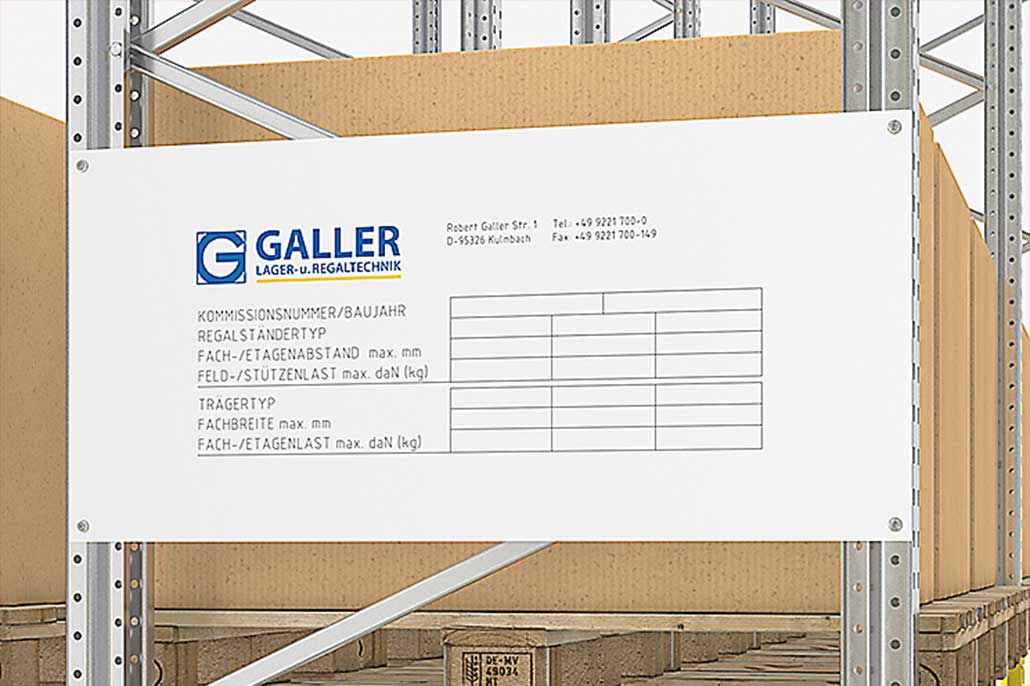

Accessories: Labelling

We also provide you with the appropriate rack signs and rack labelling systems for your rack installation. This helps you bring structure to your warehouse and comply with all legal requirements for rack labelling.

Main sign mounted centrally at the front of a large rack installation

Sign with aisle numbers

Type plate printed on adhesive foil

Location marking with/without barcode printed on adhesive foil